The Journey Begins

On February 2, 2023, I embarked on an exhilarating project to build a high power rocket capable of breaking the sound barrier. The vision for this rocket, aptly named “Mach Maxima,” was my most ambitious project to date. I chose the Mach1 Chimera 65 kit for its ability to withstand supersonic flight and quality of components. This kit includes a 65mm filament wound fiberglass nosecone with an anodized gunmetal aluminum tip, G10 fiberglass fins, and filament wound body tubes – necessary for achieving my goal.

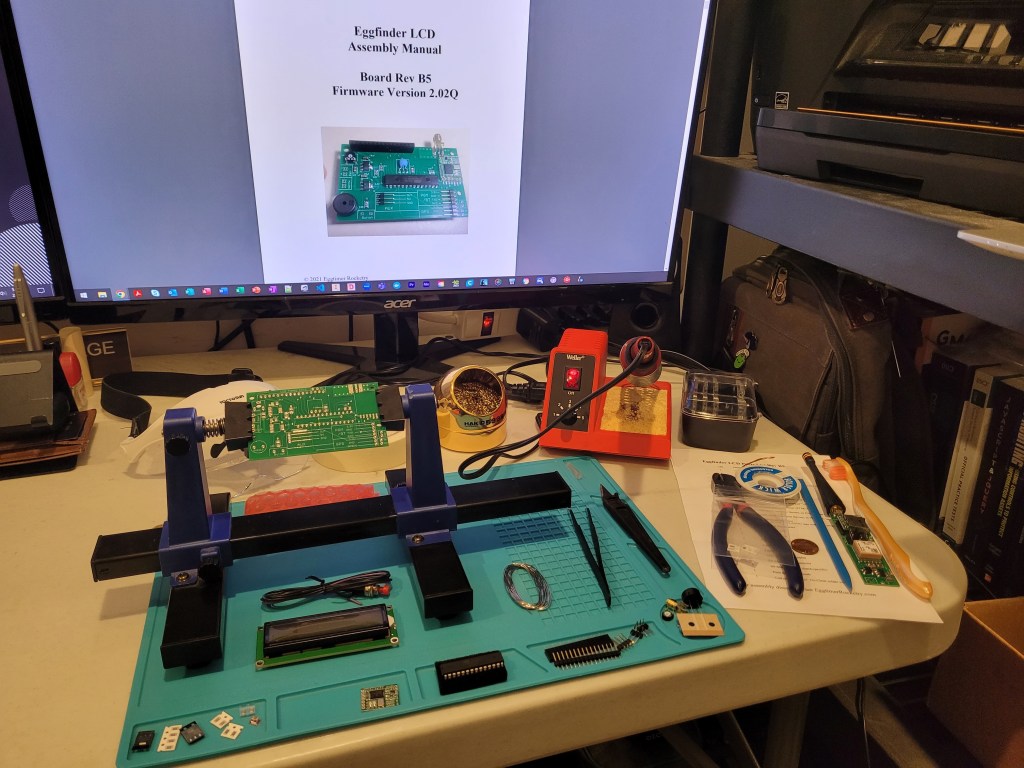

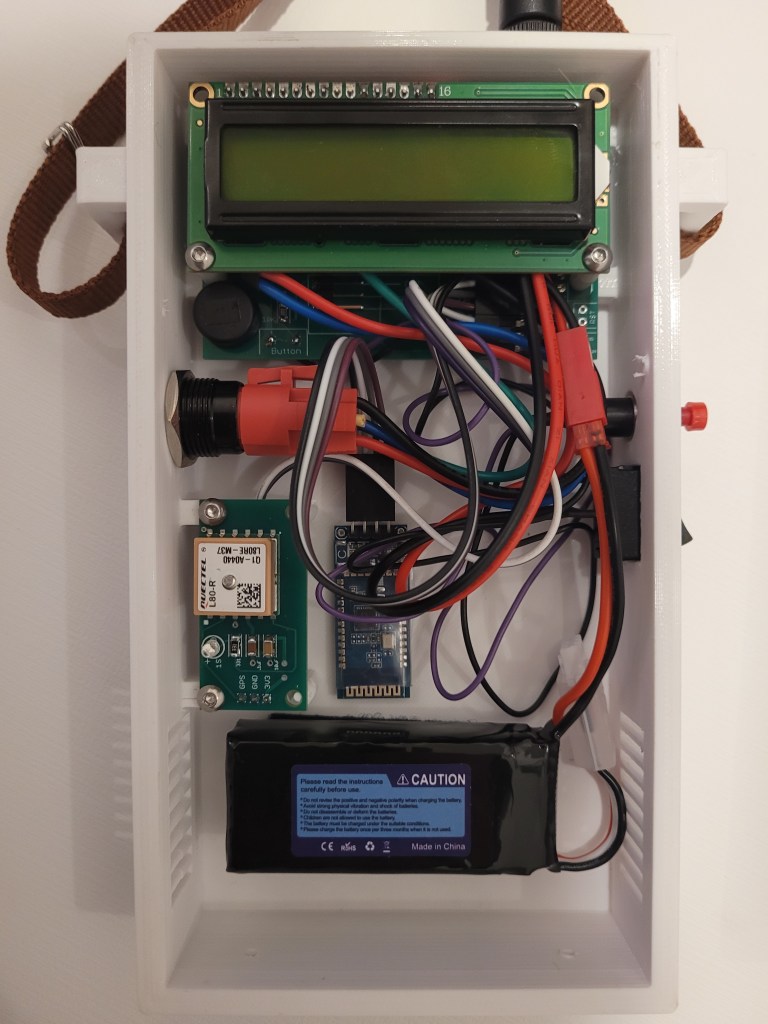

Selecting and Building the Eggfinder GPS System

Tracking the rocket during its high-speed flight was crucial. For this, I selected the Eggfinder GPS system, a reliable solution for rocketry enthusiasts. I built the system by meticulously soldering all the components and 3D printing custom electronics bays and a handheld ground station. Testing the system involved driving around my neighborhood while tracking the transmitter via Bluetooth on my cellphone. See more about building the Eggfinder kits HERE.

Building Techniques and Assembly

Injecting Epoxy Through the Fin Can

One of the essential building techniques I used was injecting epoxy through the fin can to create internal fillets. This method provides superior strength and ensures the fins remain securely attached during the intense forces of flight. Here’s a step-by-step breakdown of the process:

- Preparation: I carefully sanded the surfaces of the fins and the body tube where they would be epoxied together. Sanding is crucial as it creates a rough surface for better adhesion.

- Positioning: After dry fitting the fins to ensure proper alignment, I mixed the epoxy and injected it through small holes in the fin can.

- Injection: Using a syringe, I injected the epoxy into the fin can, ensuring it flowed around the base of each fin, creating strong internal fillets.

- Curing: I allowed the epoxy to cure completely before moving on to the next step.

Importance of Sanding Fiberglass Surfaces

Sanding fiberglass surfaces before applying epoxy is a vital step in the construction process. Fiberglass is naturally smooth, and without proper sanding, the epoxy may not adhere well, leading to weak bonds. I used fine-grit sandpaper to roughen up the surfaces, ensuring a strong and reliable bond.

Testing and Painting

Once the structural assembly was complete, I moved on to testing and painting the rocket. I conducted several ground tests to ensure all components were functioning correctly. The Eggfinder GPS system was tested by simulating flights, and I drove around my neighborhood, tracking the transmitter to verify its accuracy.

Painting the rocket was the final step before the maiden flight. I chose a sleek, aerodynamic design that minimized drag while providing a visually striking appearance. I also took some inspiration from SpaceX’s Starship heat tiles and created my own heat tile pattern using a Cricut and permanent black vinyl.

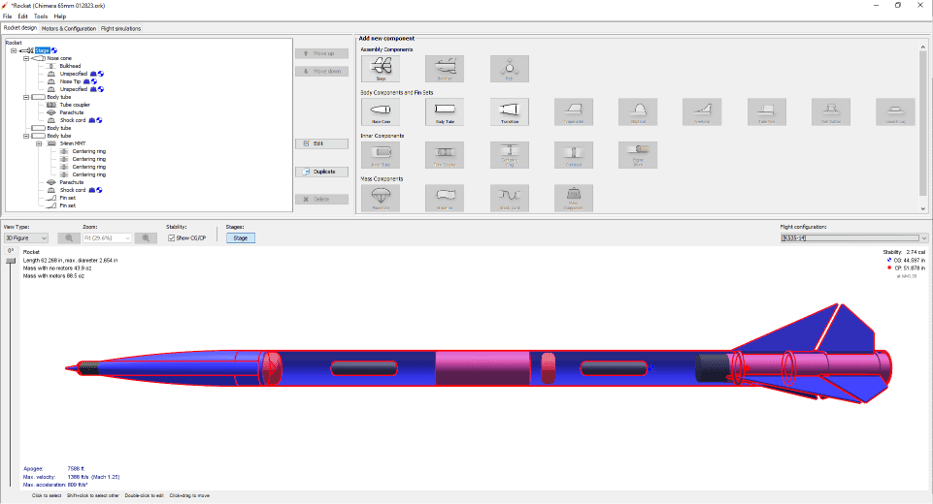

Flight Simulation and Motor Selection

Before the actual flight, I used OpenRocket to simulate different flight scenarios. This software allowed me to test various motors and wind conditions, ensuring Mach Maxima was optimized for performance. After extensive simulations, I selected the AeroTech HP-K535W motor. With a total impulse of 1,434 Ns and a burn time of 2.8 seconds, this motor provided the perfect balance of power and duration to reach supersonic flight.

The Maiden Flight

On June 11, 2023 I transported Mach Maxima to the designated launch site in Dalzell South Carolina and prepared for the critical phase of the project. After conducting a comprehensive pre-flight inspection to ensure all systems were operational and within specified parameters, the rocket was secured on the launch pad.

Upon confirming all pre-launch conditions, the launch control officer initiated the flight. The AeroTech HP-K535W motor ignited, delivering a high-thrust output that propelled Mach Maxima vertically with significant acceleration. The rocket rapidly transitioned through transonic speeds, successfully breaking the sound barrier and achieving a maximum velocity of 1,052 mph, equivalent to Mach 1.37. The recorded apogee for this flight was an impressive 9,054 feet above ground level verified both by GPS and my RRC3 altimeter.

Conclusion

The successful flight of Mach Maxima was a testament to meticulous planning, precise building techniques, and thorough testing. From selecting the Mach1 Chimera 65 kit to assembling the Eggfinder GPS system and simulating the flight in OpenRocket, every step contributed to this achievement. Breaking the sound barrier with Mach Maxima was not just a personal triumph but also an inspiring milestone in my amateur rocketry journey.

Stay tuned for more high-power rocketry adventures as I continue to push the boundaries of what’s possible in this thrilling hobby!