As I progress my skills and experience in rocketry, I had no doubts that I would set new milestones for 2023. The milestones I set for myself in 2021, as I re-entered the model/sport rocketry hobby, were to obtain my NAR Level I certification and successfully launch and recover my first high-powered rocket. The milestones I set for 2022 were to obtain my NAR Level II certification and launch a high powered model rocket to an altitude of at least 1 mile. I successfully reached all these milestones, and the beginning of 2023 left me with one question… now what? Luckily, one thing is for certain – there is no shortage of rocketry projects to build!

After spending a weekend browsing the internet for ideas I kept coming back to one concept, breaking the sound barrier. Doing so would require building my first all fiberglass rocket to survive subsonic, transonic, and supersonic flight and implementing a GPS tracking system to ensure recovery. Even with smaller high-powered rockets and motors, the velocities and altitudes associated with supersonic flight mean any deviation from the planned trajectory could put the rocket landing miles away from the launch pad. Hence, onboard GPS is essential if you don’t want to lose your flight hardware.

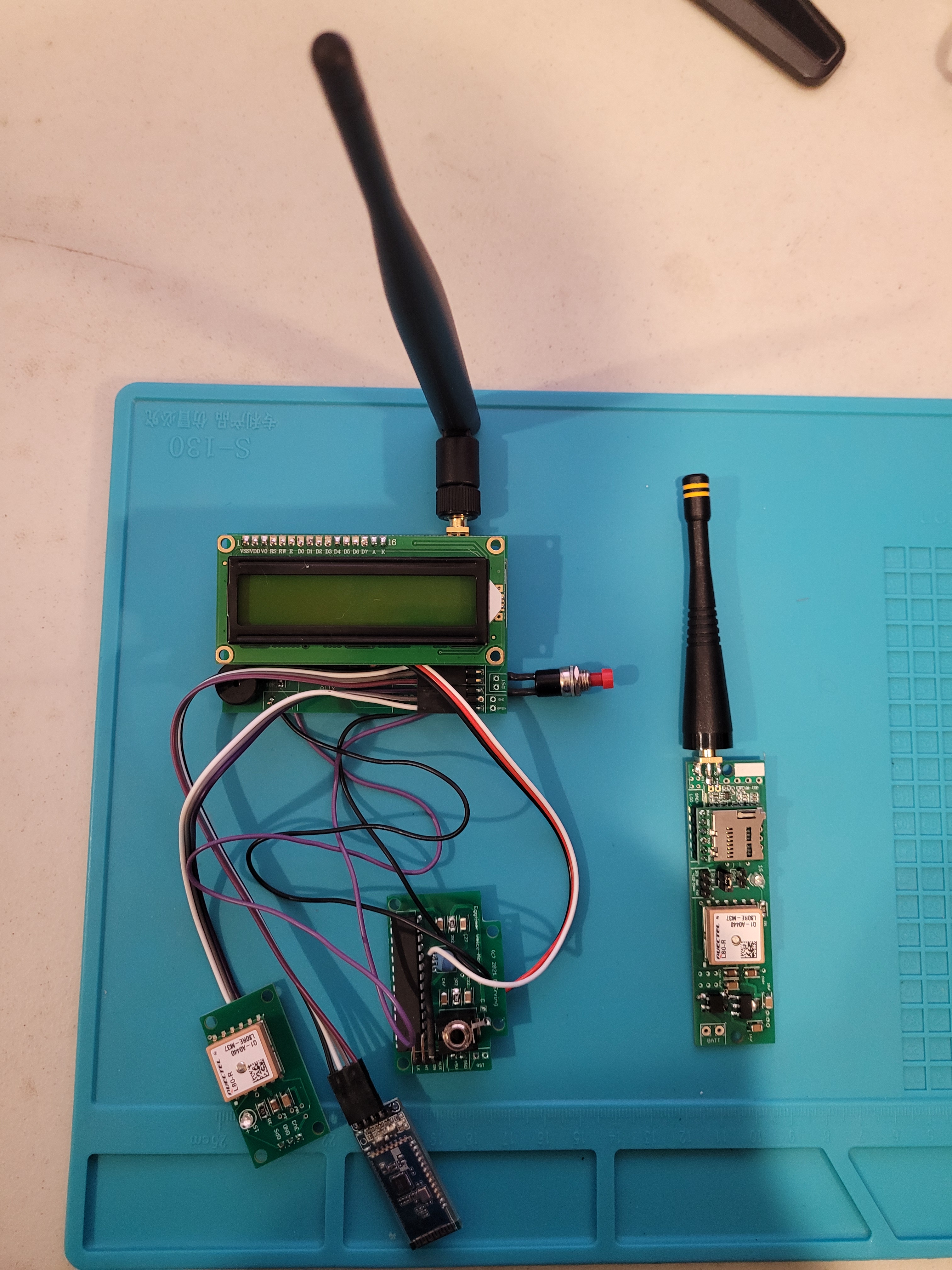

After some extensive research on currently available GPS systems, I found a company in California that produces GPS hardware specific to rocketry (although you could use it for other applications). You can check them out HERE. They sell their products as kits, which transmit a stream of NMEA-formatted serial data from a transmitter located in the rocket to a receiver on the ground. The data can also be fed real-time into a number of software programs (e.g. Google Earth or Map Sphere) to track the rocket. Using a GPS-enabled smartphone (like an iPhone or Android) and their plug-and-play Bluetooth module, you can even transmit the GPS coordinates into an app such as GPS Rocket Locator.

The GPS components I am using for my tracking system include:

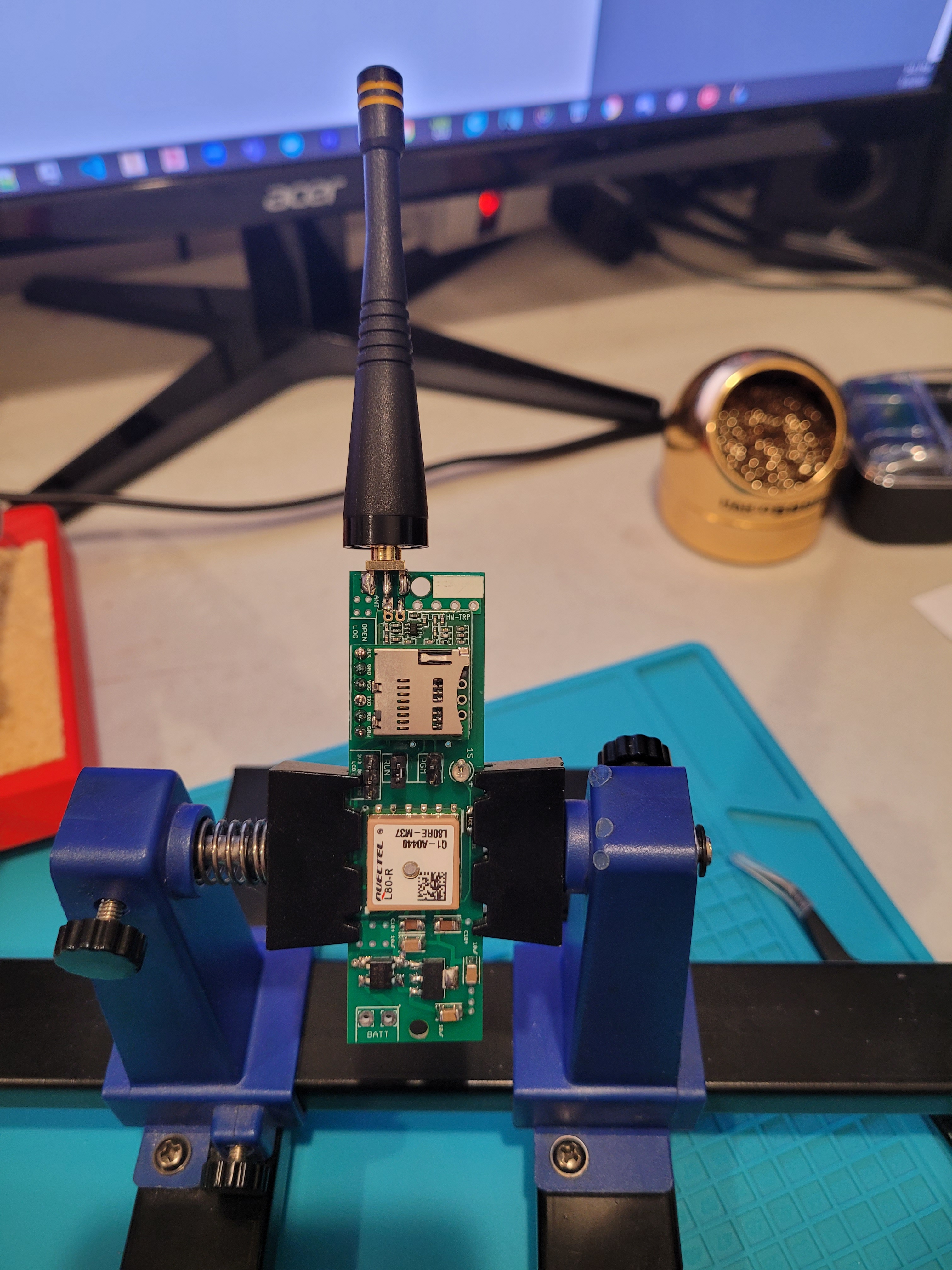

- TX Transmitter with RP-SMA + 3 dB External Antenna

- OpenLog Data Logging Module

- LCD Receiver

- Voice (audio) Module

- LCD-GPS Module

- BT06 Bluetooth Module

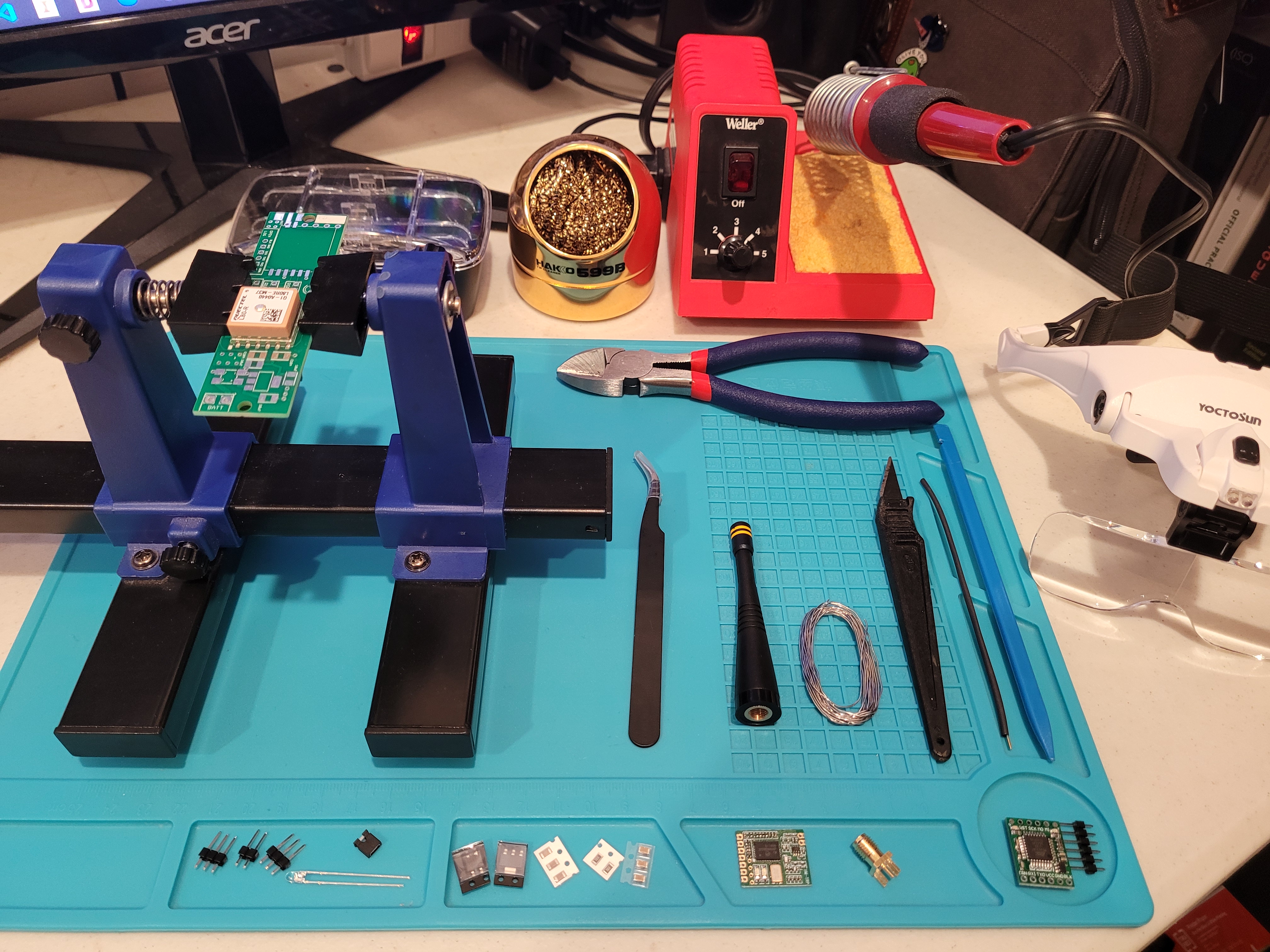

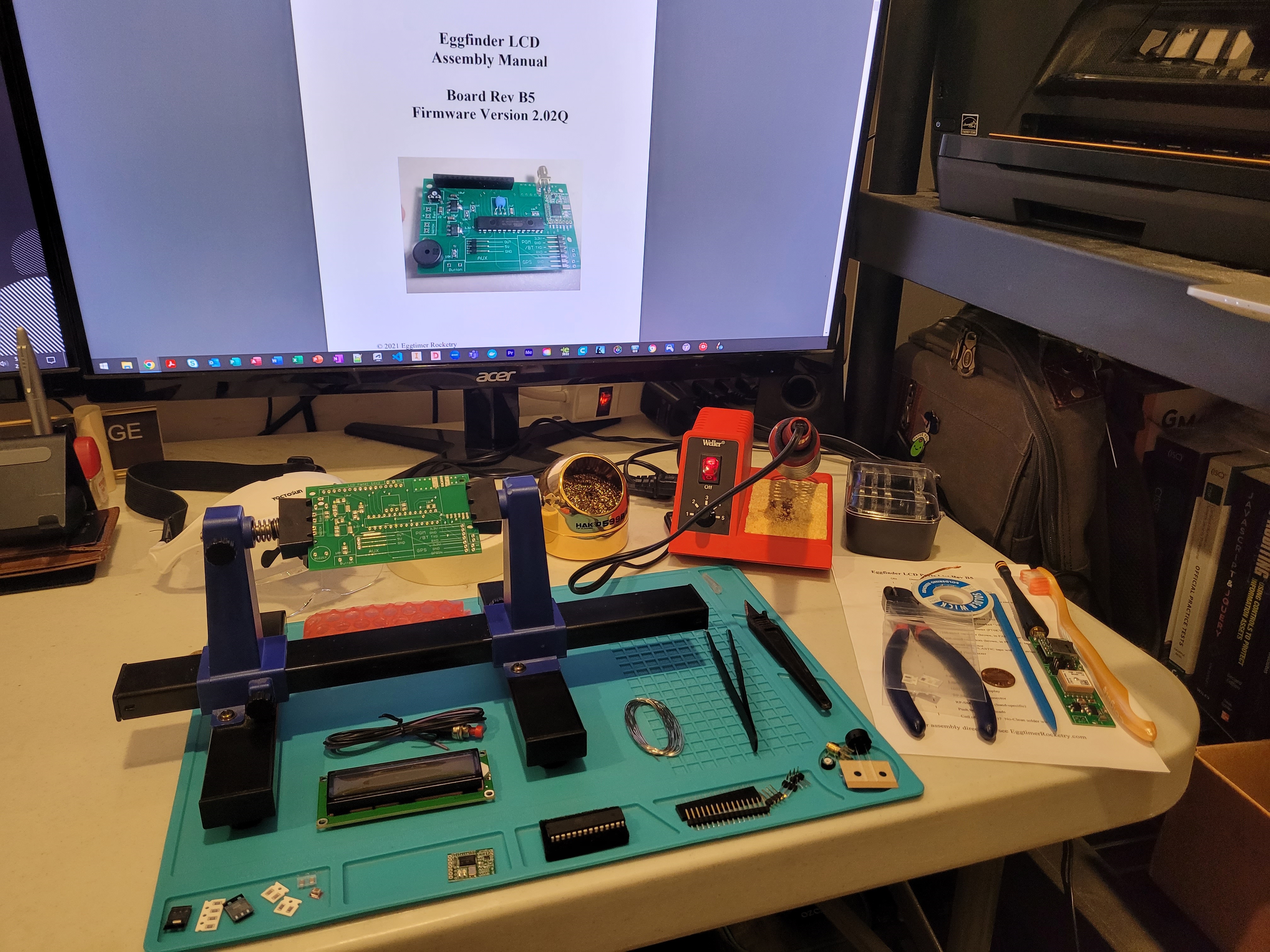

Most of the components require soldering small 0805 surface mount parts and have .050″ pitch IC’s. The company rates the assembly of their products on a level of difficulty ranging from 1-5 with the average difficulty of my components being a 4. Soldering/electronics experience and a proper soldering setup is highly recommended for this system (anti-static silicon mat, magnifying lens, electronics vice), although not completely necessary.

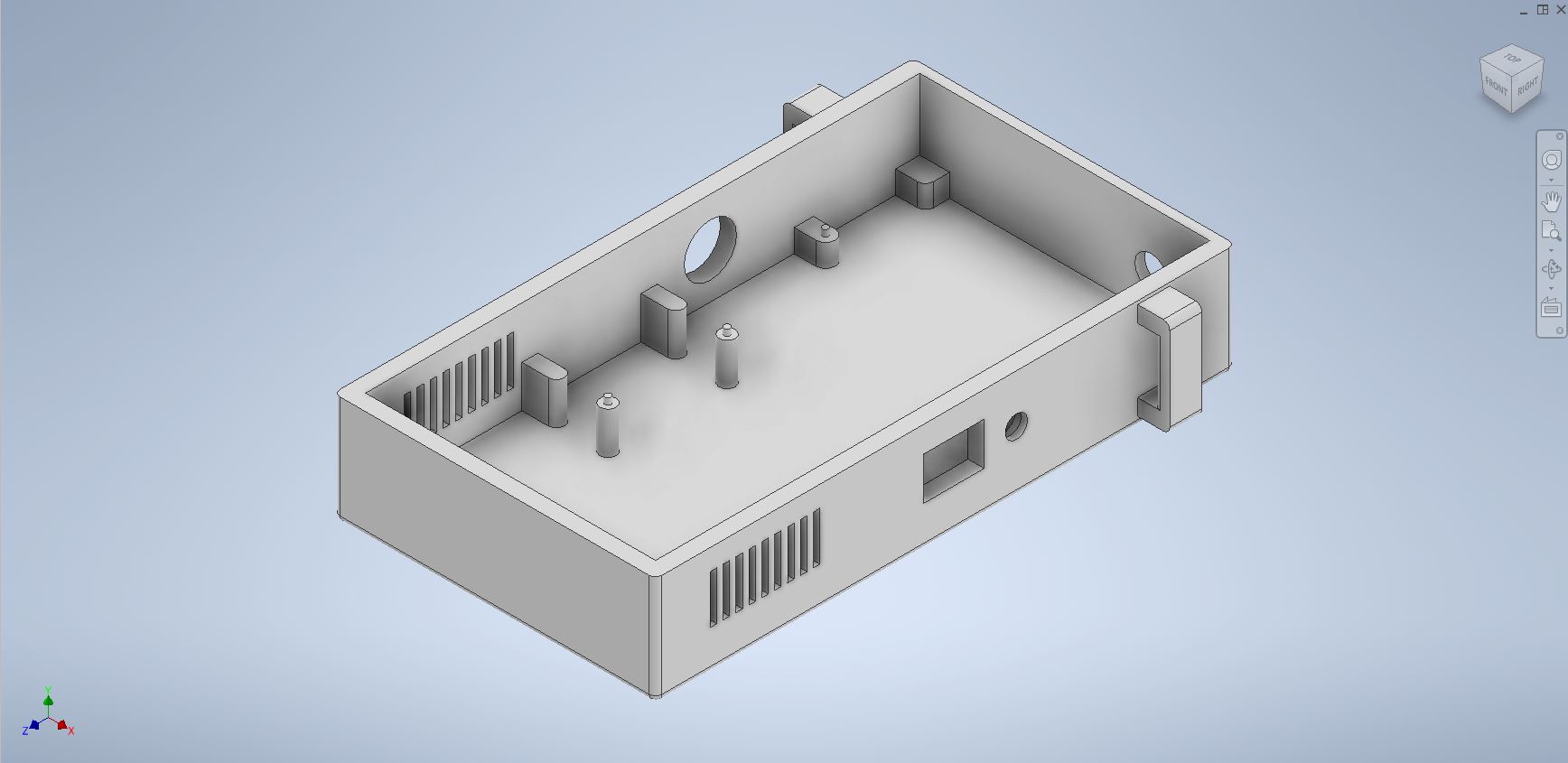

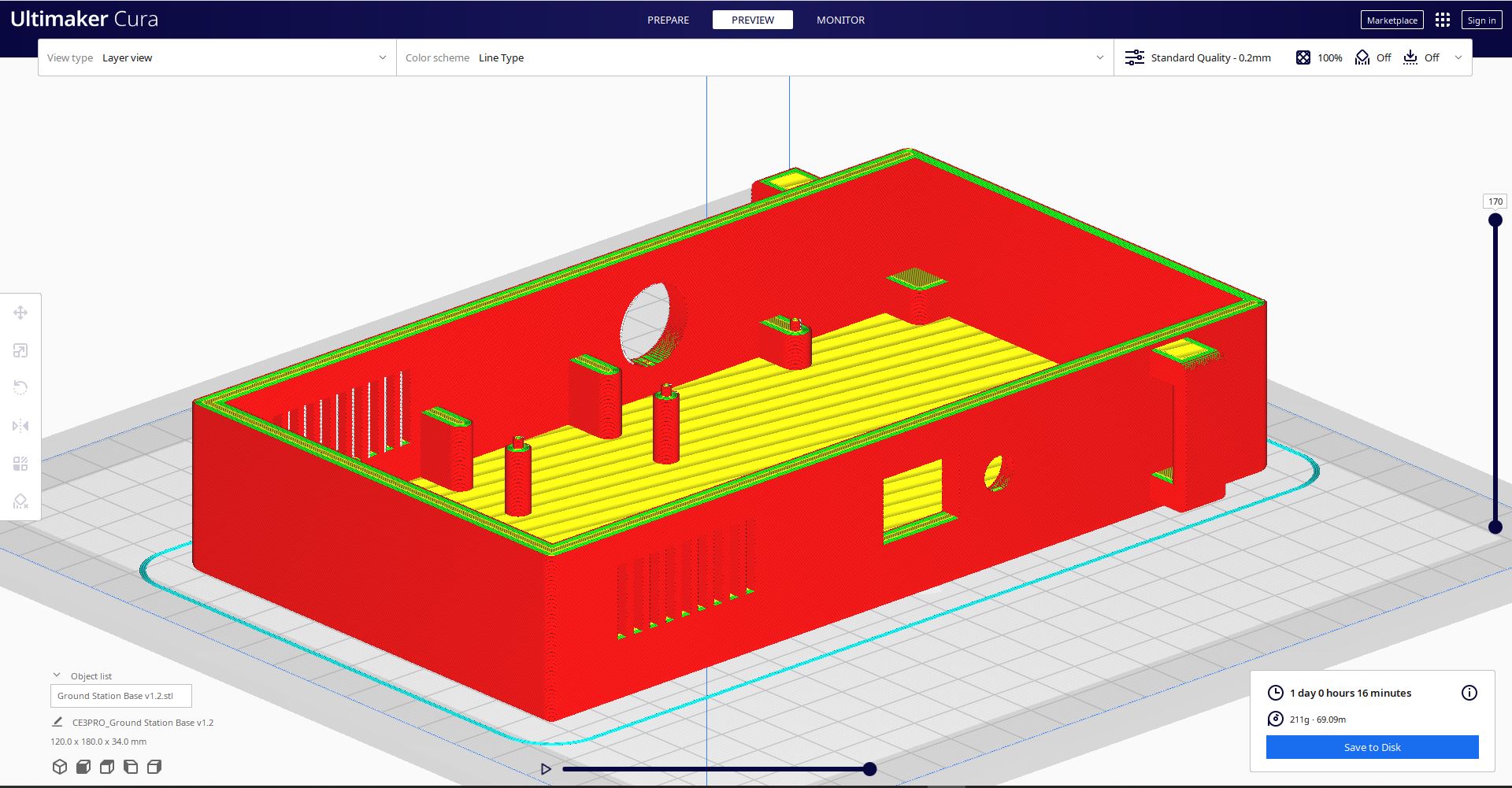

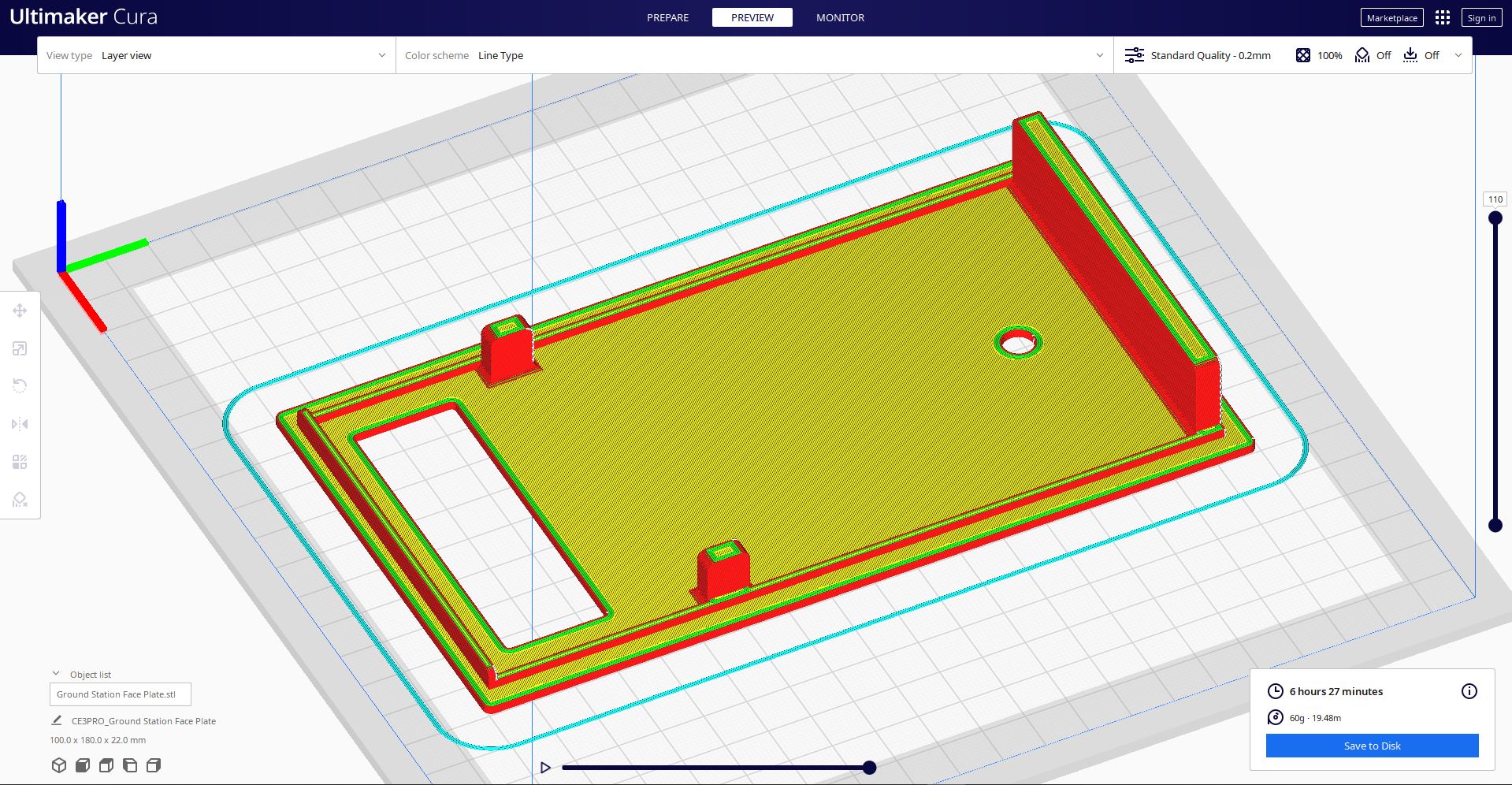

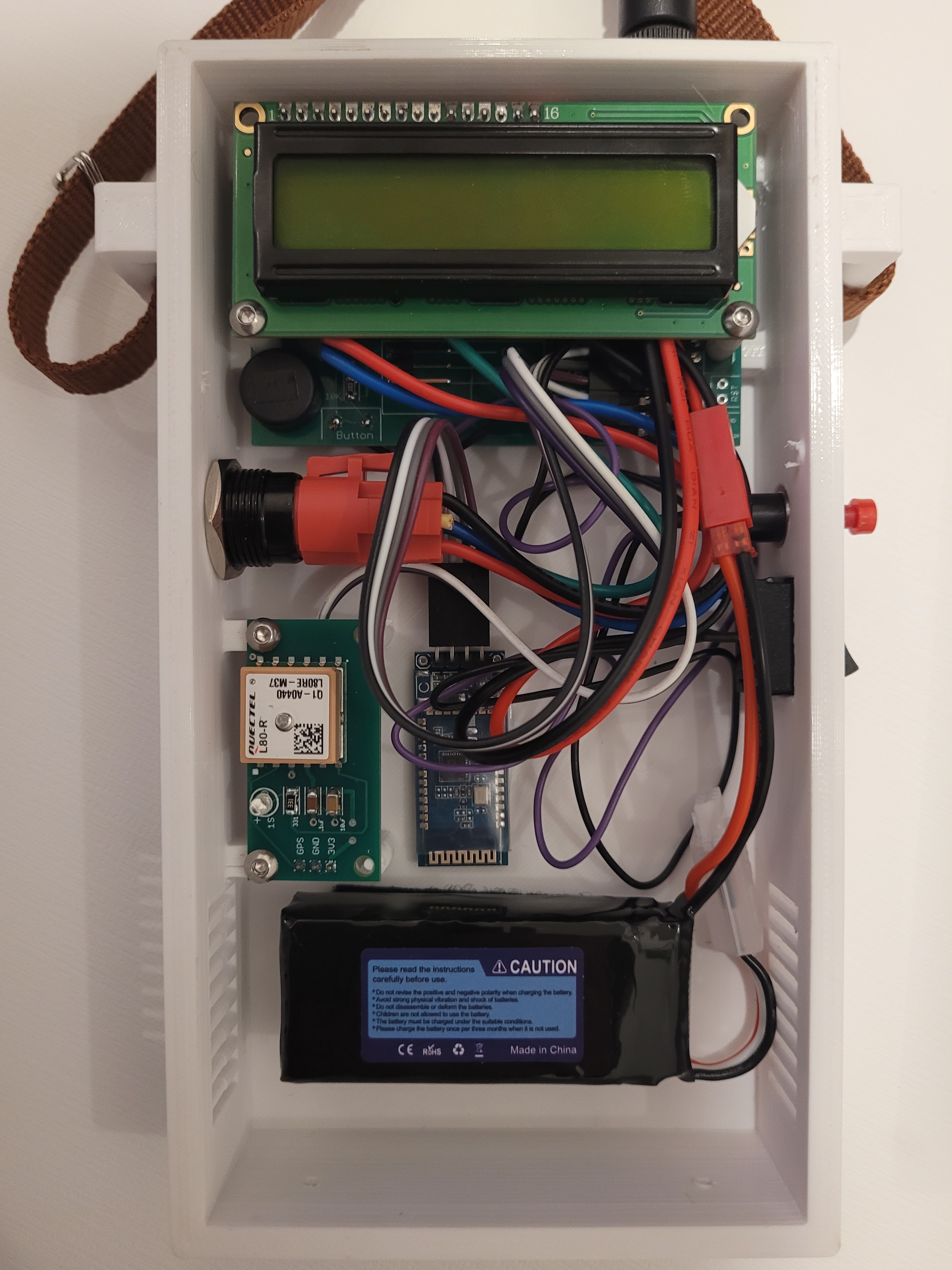

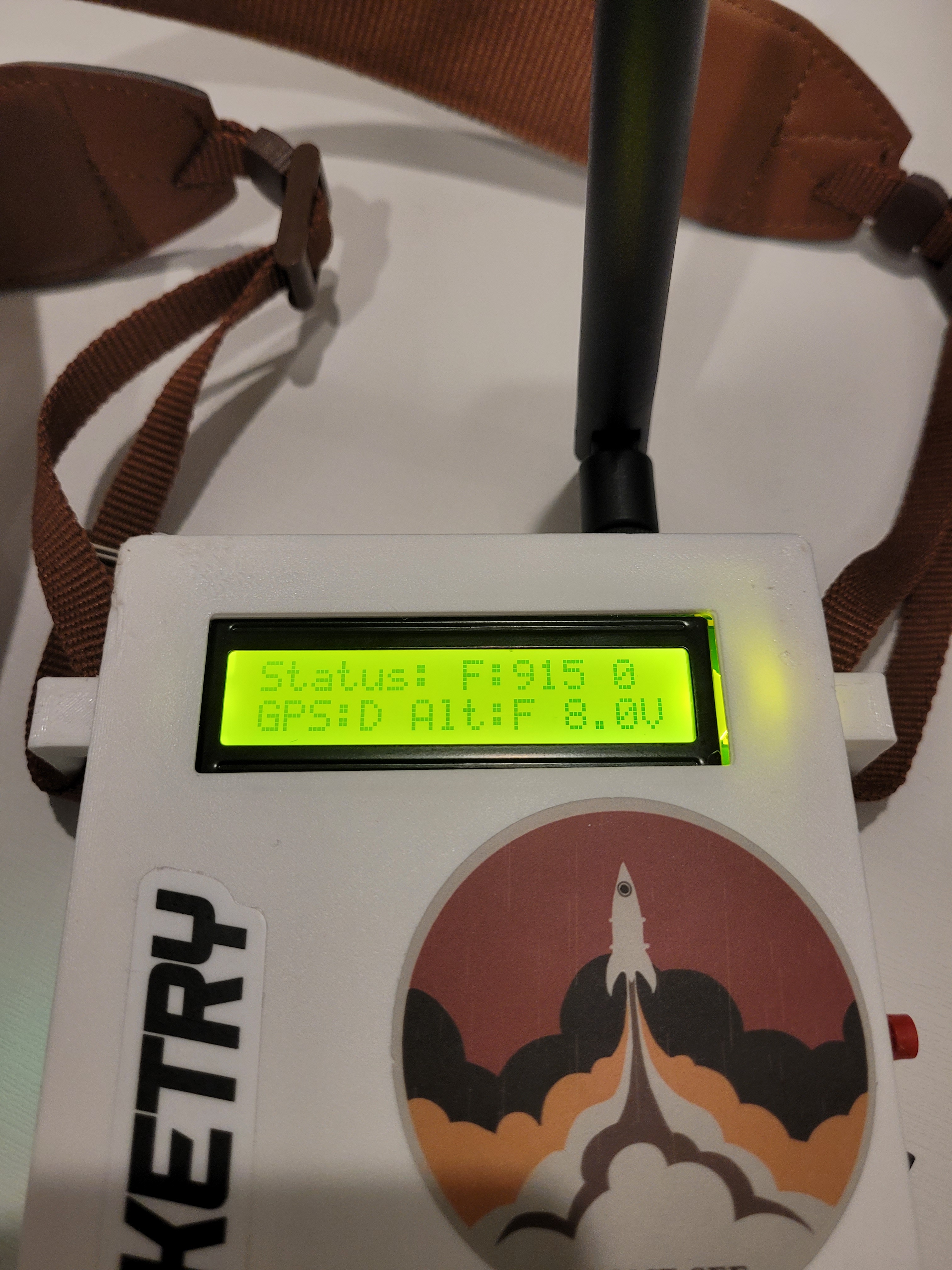

I also designed and 3D printed my own handheld enclosure to house the ground station electronics including GPS receiver, LCD screen, audio module, and Bluetooth module. The entire handheld system is powered by a 2S 1400mah LiPo battery. I incorporated a rocker switch to turn the LCD backlight on/off, and a push-button latching switch with a green LED halo for the power switch.

Download my custom handheld STL files HERE!

Overall, I designed, 3D printed, and assembled the entire system in one week and the process was pretty straightforward. The use of a good pair of calipers assisted tremendously with the design of the enclosure and it took me three iterations of printing to get it perfect with all of the features I wanted. I spent about an hour testing the system outside and tracking the GPS transmitter using both the handheld ground station and Google Maps on my Samsung Galaxy Note20. With the GPS system complete, it’s time to build a rocket!

Build and Assembly Photos